Introduction

Ultrasonic testing is a nondestructive evaluation (NDE) method that uses high-frequency sound waves to detect the presence of defects in materials. Ultrasonic testing is an effective way to examine welds for cracks, slag inclusions, porosity, incomplete fusion, and planar flaws.

Ultrasonic inspection refers to the process of detecting flaws and discontinuities in materials by means of ultrasonic waves.

Ultrasonic inspection refers to the process of detecting flaws and discontinuities in materials by means of ultrasonic waves. The technology is commonly used to inspect welds, cracks, missing metal, and other flaws in a wide range of industrial products including aircraft components and castings. The technology can also be used to measure thicknesses or identify other characteristics such as porosity or voids within materials.

In this context, we will consider an ultrasonic inspection technique known as “Time Domain Reflectometry” (TDR). This method involves transmitting ultrasonic pulses into the material and measuring their reflection back from various interfaces within that material. If there is an absence of material at one interface, then no reflection will occur; if there is missing material then this will cause a reduction in amplitude on reflection from that point relative to its normal value; if there are micro cracks present then these will also reflect differently than expected due to differences in impedance induced by their presence relative to undamaged areas.”

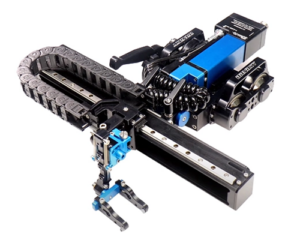

Phased Array Ultrasonic Testing (PAUT) is a newer technique that can perform the same functions as conventional or immersion UT testing.

Phased Array Ultrasonic Testing (PAUT) is a newer technique that can perform the same functions as conventional or immersion UT testing. PAUT uses multiple elements, transducers and receivers, to provide a phased array for positioning in the weld area. This allows for high sensitivity and excellent performance on difficult-to-reach weld areas, as well as internal weld inspection for cracks, slag inclusions, porosity, incomplete fusion, and other defects.

Time of Flight Diffraction (TOFD) is a technique for examining welds for defects, like incomplete penetration, lack of fusion, and planar flaws.

Time of Flight Diffraction (TOFD) is a technique for examining welds for defects, like incomplete penetration, lack of fusion and planar flaws. This application focuses is a very good sizing and screening tool as it is not dependent on the reflected amplitude or signal response, making it ideal for detecting transverse anomalies.

Ultrasonic inspection can be used for internal weld inspection to reveal cracks, slag inclusions, porosity, incomplete fusion, and another defects.

Ultrasonic inspection is used for internal weld inspection to reveal cracks, slag inclusions, porosity, incomplete fusion and another defect. Ultrasonic testing is a nondestructive examination method that provides information on the integrity of components. It can also be used to detect flaws or defects in materials or welds.

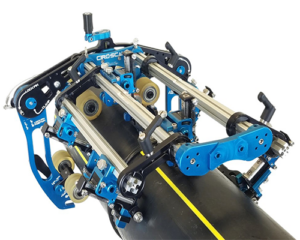

Ultrasonic corrosion mapping is a tool used to monitor corrosion rates of equipment and piping in oil refineries.

Ultrasonic corrosion mapping is a tool used to monitor corrosion rates of equipment and piping in oil refineries. It is also used to detect corrosion in oil pipelines, storage tanks, and other equipment. Ultrasonic corrosion mapping is accomplished by comparing the frequencies at which an object reflects an ultrasonic signal with the frequency of the original signal (the “base” frequency). A difference indicates that there has been some chemical reaction from which sound waves cannot escape, i.e., corrosion has occurred.

The use of ultrasonic testing has some advantages over radiography or liquid penetrant testing.

The use of ultrasonic testing has some advantages over radiography or liquid penetrant testing. Ultrasonic waves penetrate materials faster than x-rays and do not require the development of the film. The time required for inspection is shorter than that required for radiography or liquid penetrant testing, and the equipment can be made smaller and more portable. In addition, the ultrasonic inspection does not require any direct contact with the specimen being tested, which makes it very useful in situations where contamination cannot be tolerated. Ultrasonic testing is non-destructive (that is, it does not modify or weaken a material being tested), so it can be used on an item without permanent modification if considerations are taken into account regarding material properties such as hardness or toughness when selecting probes for specific types of tests.

Conclusion

Ultrasonic testing can be used to detect internal welds in pipes and vessels, cracks, and flaws in piping, shafts, and other equipment. It is also useful in detecting corrosion rates of equipment and piping in oil refineries. This technique has been used for many years but has recently become more sophisticated due to increasing computer capabilities which allow for more detailed analysis

Please enter your info and we’ll send you a link to download your PDF.

Please enter your info and we’ll send you a link to download your PDF.