PHASED ARRAY NDT

Raise Face Flange Face Inspection

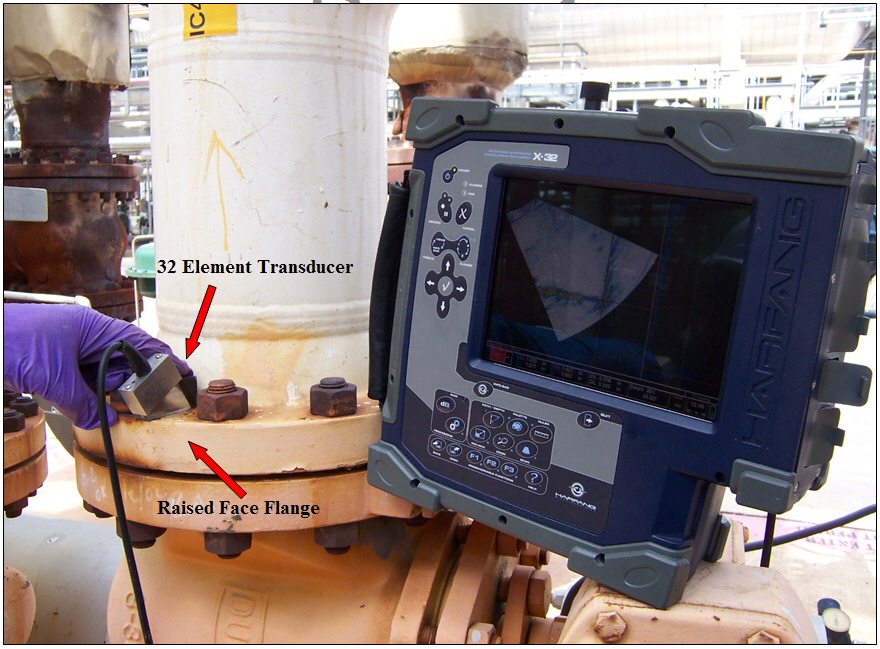

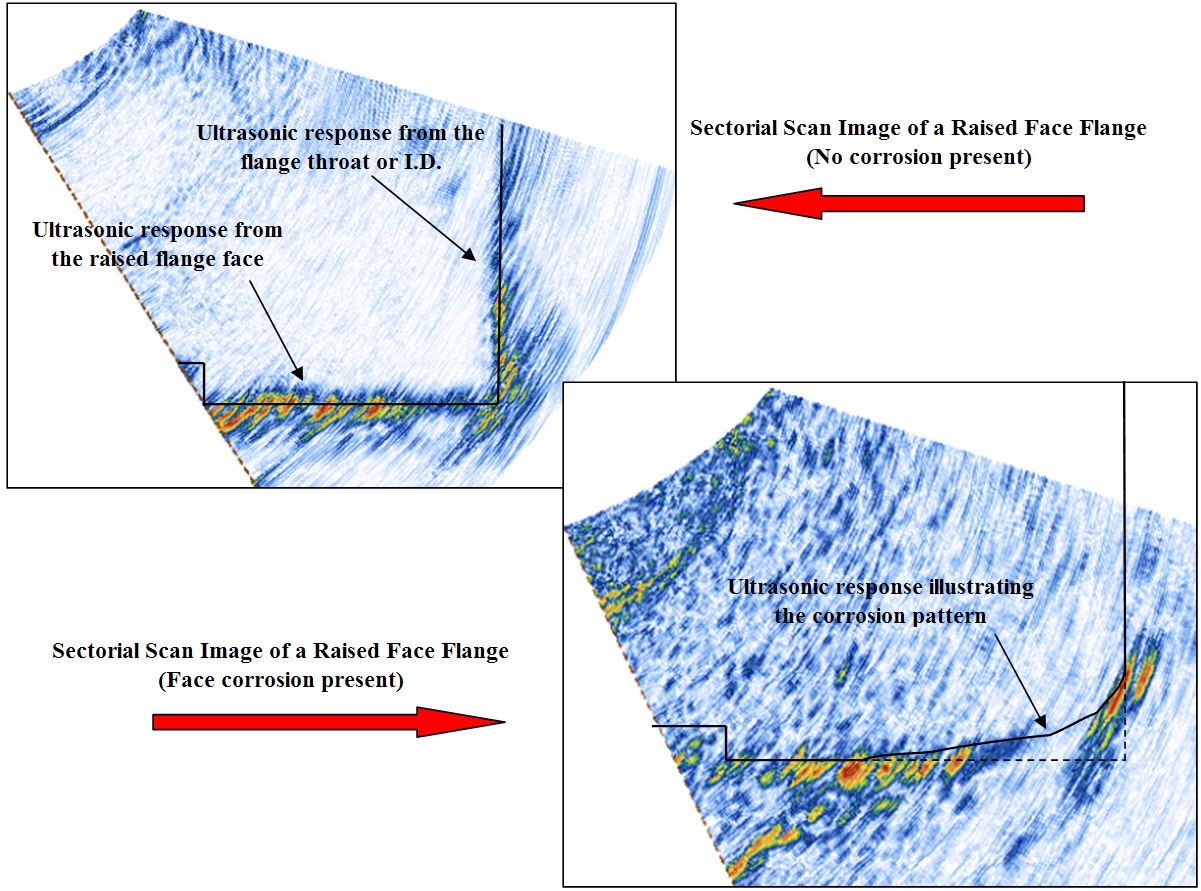

Utilizing this phased array technologies allows for inspection of complex geometries, which are generally too difficult to performed with conventional ultrasonic techniques. Phashed array opens the door for inspections that are thought to be impossible or impractical. One of these ‘impossible’ examinations is the inspection of Raised Face Flanges.

When raised face flanges are used in very corrosive environments such as hydrofluoric acid (HF) or C02 service, the flange face is susceptible to corrosion which in turn can lead to subsequent failure. With our phased array technique and specially designed probes & wedges, the flange face can be inspected with detection capabilities as low as 0.020” from the flange face.

Please enter your info and we’ll send you a link to download your PDF.

Please enter your info and we’ll send you a link to download your PDF.